11 2023 - 11 2024

Conductive Seam Research Project at SciFi Lab (Cornell University)

Co-author on Published Paper

Research Advisors: Cheng Zhang, Francois Guimbretiere

Collaborators: Tianhong (Catherine) Yu, Manru (Mary) Zhang, et al.

SeamPose and SeamFit

Seams are areas of overlapping fabric formed by stitching two or more pieces of fabric together in the cut-and-sew apparel manufac- turing process. In SeamPose, we repurposed seams as capacitive sensors in a shirt for continuous upper-body pose estimation. Compared to previous all-textile motion-capturing garments that place the electrodes on the clothing surface, our solution leverages exist- ing seams inside of a shirt by machine-sewing insulated conductive threads over the seams. The unique invisibilities and placements of the seams afford the sensing shirt to look and wear similarly as a conventional shirt while providing exciting pose-tracking ca- pabilities. To validate this approach, we implemented a proof-of-concept untethered shirt with 8 capacitive sensing seams. With a 12-participant user study, our customized deep-learning pipeline accurately estimates the relative (to the pelvis) upper-body 3D joint positions with a mean per joint position error (MPJPE) of 6.0 cm. SeamPose represents a step towards unobtrusive integration of smart clothing for everyday pose estimation.

SeamFit features washable T-shirts of different sizes with seam electrodes to log exercises. Smart clothing has exhibited impressive body pose/movement tracking capabilities while preserving the soft, comfortable, and familiar nature of clothing. For practical everyday use, smart clothing should be available in a range of sizes to accommodate different fit preferences, andbe washable to allow repeated use. In SeamFit, we demonstrate washable T-shirts, embedded with capacitive seam electrodes, available in three different sizes, for exercise logging. Our T-shirt design, customized signal processing & machine learning pipeline allow the SeamFit system to generalize across users, fits, and wash cycles. Prior wearable exercise logging solutions, which often attach a miniaturized sensor to a body location, struggle to track exercises that mainly involve other body parts. SeamFit T-shirt naturally covers a large area of the body and still tracks exercises that mainly involve uncovered joints (e.g., elbows and the lower body. In a user study with 15 participants, performing 14 exercises, SeamFit detects exercises with an accuracy of 89%, classifies exercises with an accuracy of 93.4%, and counts exercises with an error of 0.9 counts, on average. SeamFit is a step towards practical smart clothing for everyday uses.

SeamPose is a published paper and has been presented at the UIST ‘24 Conference. SeamFit has been conditionally accepted to IMWUT.

For more details about SeamPose: https://dl.acm.org/doi/10.1145/3654777.3676341

Data Processing and Machine Learning Pipelines

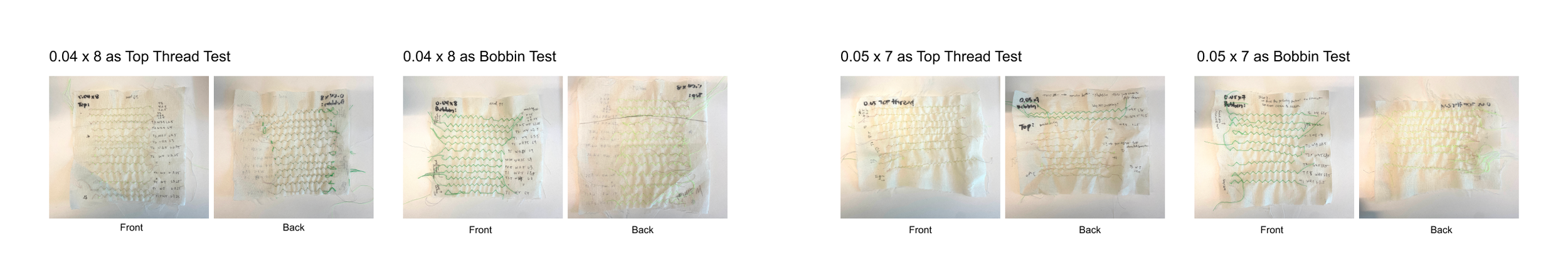

Initial Material and Fabrication Testing

Initial Litz Wire Experimentation: Although not used in our final prototype, we experimented extensively with Litz Wire, hoping to seek an even less obtrusive and natural conductive thread. However, it was not robust enough for the purpose of this research project.

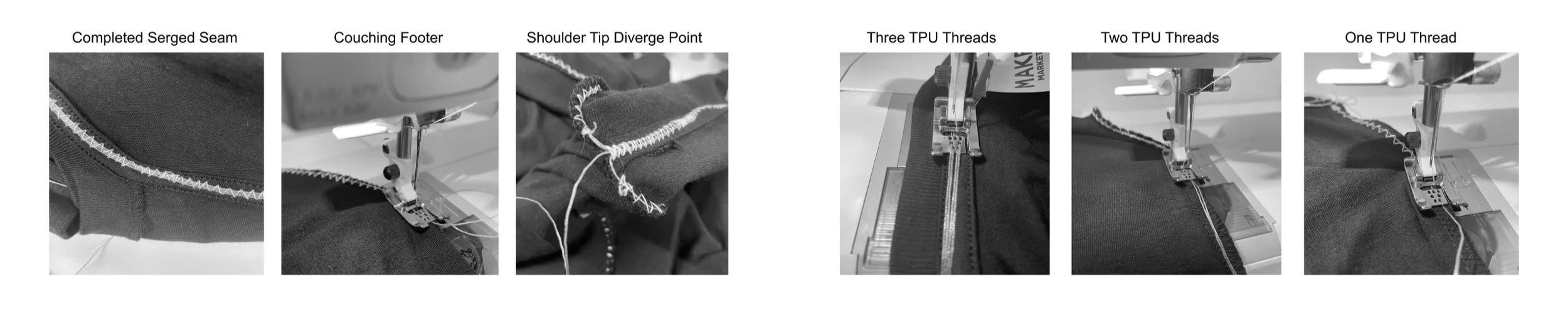

Couching with TPU Experimentation: Couching is a traditionally embroidery fabrication process. However, we repurposed it for SeamFit to make it easier for the TPU threads from staying put and not breaking like it would if it was threaded through the top thread or bobbin.

Industrial Sewing Machines Experimentation: While being very robust, the industrial sewing machines available could only sew straight stitches which does not fulfill the needs of our project.

Serging Experimentation: Initially, serging was the most professional and clean sewing process but it is hard to control with the attributes of conductive threads and it was difficult to find the breaking point if there were any throughout the serged seam